Reduce risk and maintain compliance with our specialist risk management services.

We’re proud to be a leading provider of complete life cycle risk management solutions. From ensuring asset safety and legal compliance with our thorough engineering inspections to driving operational efficiency with our specialist non-destructive testing services, (and much more in between), we’re proud of the long-lasting partnerships we have formed with our customers over the last 160 years, based on the value of our solutions.

Condition-Based Maintenance

Preventing unexpected downtime of business critical assets

For most businesses, unscheduled downtime caused by an unexpected failure on a highly critical piece of equipment is simply not an option. At BES Group, our Condition-based Maintenance (CBM) service offering can help you and your business to prevent unplanned downtime by monitoring the condition of your equipment and identifying potential problems before they lead to failure. Through services that include corrective solutions, In-Situ Balancing and Laser Alignment, we offer a comprehensive, holistic approach that safeguards the reliability and efficiency of your equipment and operations.

Minimise downtime and boost efficiency with our CBM service offering

CBM enables your business to monitor the condition of your equipment and identify potential problems before they reach failure, saving valuable time and money through minimising downtime

If your business relies heavily on the seamless operation of its assets then CBM can be a valuable tool. By proactively monitoring the condition of your assets and taking action before they fail, far reaching implications can be avoided and total business continuity can be improved. You can rest assured that partnering with our team at BES Group will mean we provide you with the expertise, capabilities and tools to tackle all of your toughest maintenance challenges and CDM requirements.

Unlock the full potential of your assets with our cutting-edge CBM services.

Schedule a call! Schedule a call! Schedule a call!

Challenges your equipment may be experiencing

The decision to implement CBM at your plant can depend on several factors, It can be a wise investment if your assets are vulnerable to any of the following reliability challenges:

- Unacceptable levels of plant downtime: If your business assets are requiring increasing levels of corrective maintenance tasks to run properly you could experience unplanned downtime, which can be costly and disruptive, leading to lost productivity and revenue.

- High percentage level of intrusive maintenance activity: If your plant is spending a lot of time and money on maintenance that requires equipment to be taken offline.

- Operational, maintenance, project asset care and support service work are not efficiently delivered: If your plant is not getting an efficient, timely and reliable service, this can compound issues causing downtime and productivity

- Site delivery resources are not effectively utilised: If your plant is not using its people and equipment in the most efficient way possible, there could be a far reaching impact on productivity.

- Planned preventative Vs predictive maintenance balance is poor: If your plant is not doing enough to prevent problems from happening in the first place you could be facing unplanned downtime and increased costs.

- Ineffective workflow management and control procedures: If your plant does not have a good system for tracking and managing maintenance work, overall efficiency could be impacted significantly.

How we'll work with you

1. Review

The foundation of a successful CBM implementation lies in a comprehensive understanding of your current maintenance practices and the unique challenges faced by your plant.

Our experienced team embarks on a thorough evaluation of your EPM (Enterprise Asset Management) system, meticulously analysing your asset list, maintenance schedules, and historical data. This in-depth assessment reveals hidden inefficiencies, untapped potential, and areas where CBM can deliver significant benefits.

Key insights from the assessment:

- Identification of critical assets that demand the highest level of maintenance attention

- Unveiling hidden maintenance costs and potential savings

- Mapping out the gaps between current practices and optimal CBM implementation

- Tailoring a CBM program that aligns seamlessly with your unique operating environment

2. Site scope

Our expert reliability consultants embark on a comprehensive site walk-through, gaining an immersive understanding of your plant’s layout, asset distribution, and operational processes.

This first-hand experience allows us to identify the critical assets that play a pivotal role in your plant’s overall performance. These essential components, when prioritised, ensure that your CBM efforts are focused on the assets that demand the highest level of attention and maintenance resources.

Asset identification criteria:

- Assets with high failure rates or potential catastrophic consequences

- Assets with complex operating conditions or significant environmental factors

- Assets that impact production output or overall plant performance

- Assets with long downtime or high repair costs

3. Setup

To ensure a seamless transition to CBM, we conduct an initial baseline survey for each monitored asset. This involves collecting relevant data points and analysing their trends to establish a baseline condition for each asset.

This baseline serves as a reference point, allowing us to identify any deviations or anomalies that indicate potential issues. Additionally, we provide comprehensive training to your maintenance team, familiarising them with the various CBM technologies, their applications, and the interpretation of data insights.

Training objectives:

- Equipping your team with the knowledge and expertise to effectively utilise CBM data

- Facilitating informed decision-making and proactive corrective actions

- Enhancing understanding of asset health and potential failure modes

- Integrating CBM data into existing maintenance management workflows

4. Data collection

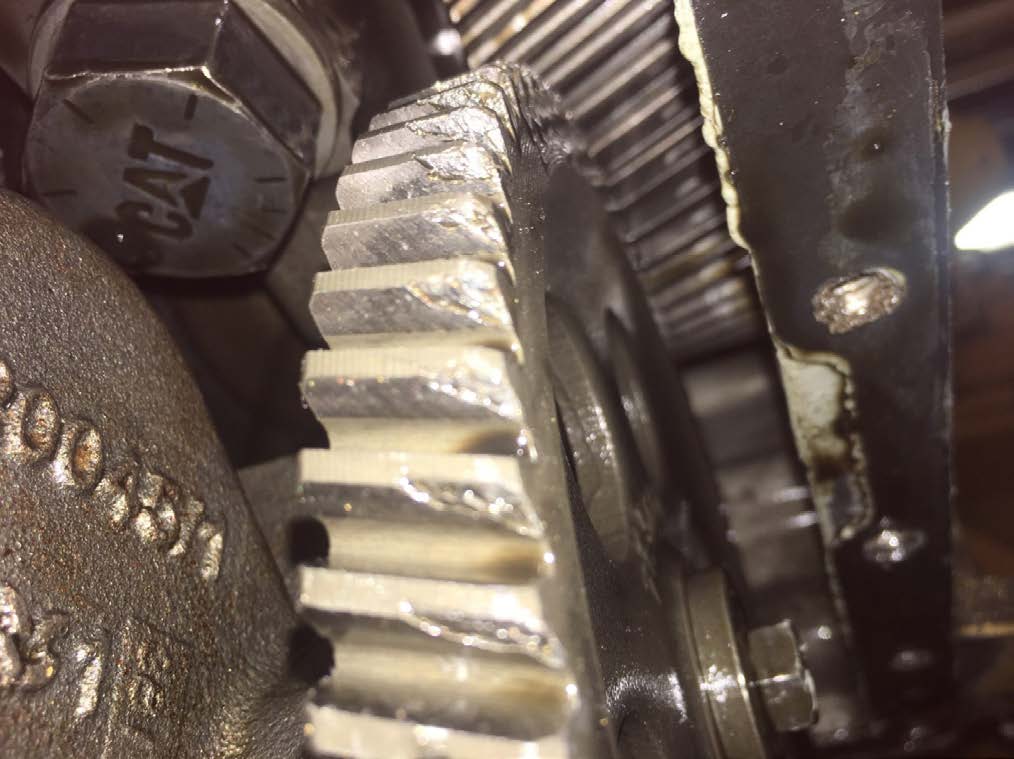

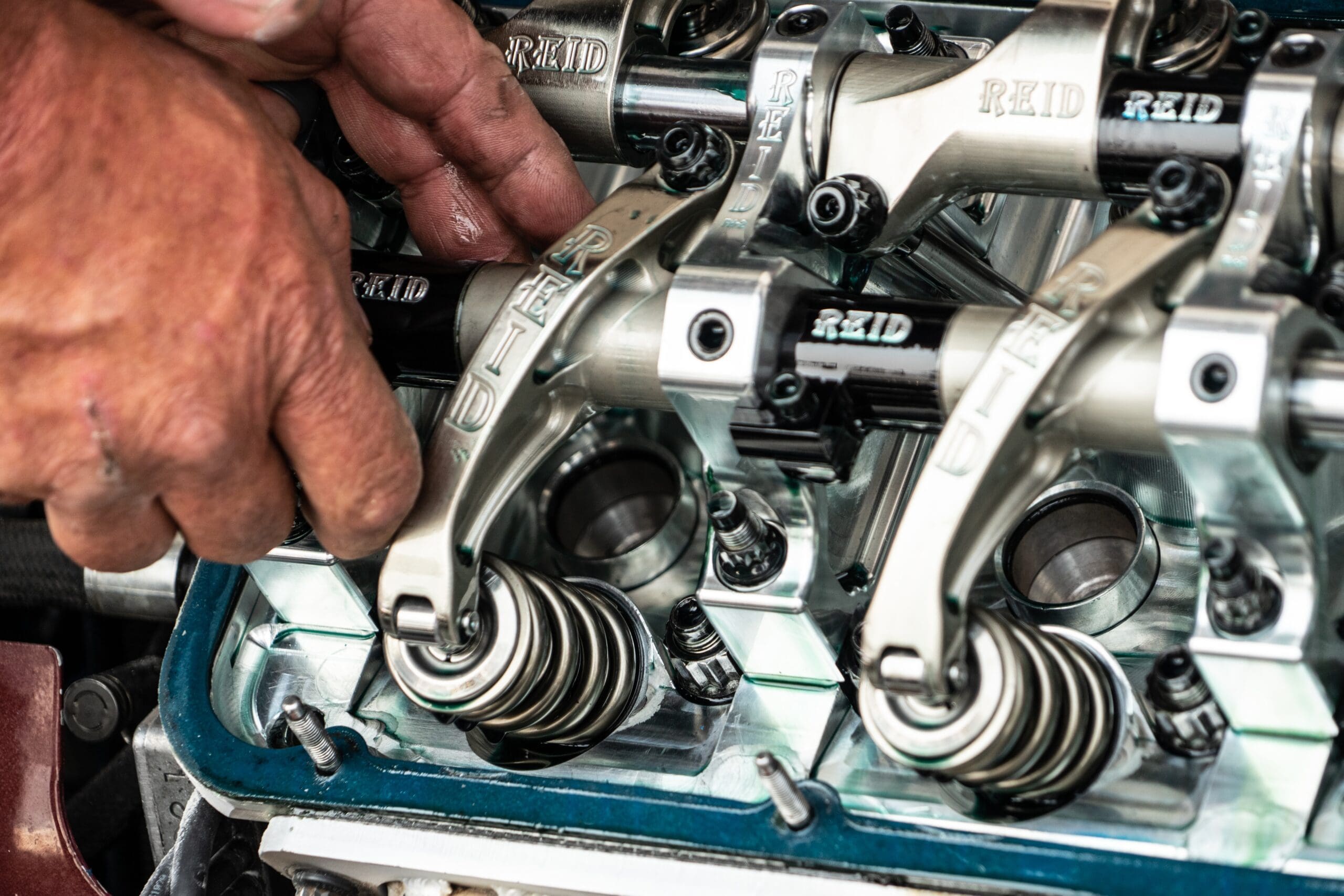

Our team of engineers and consultants employs a combination of advanced monitoring technologies, including vibration analysis, infrared thermography, ultrasonics, and oil analysis.

This multi-pronged approach provides a holistic view of the asset’s health, enabling us to capture a comprehensive understanding of its performance and potential failure modes.

Technology applications:

- Vibration analysis: Detects subtle changes in machinery operation, indicating potential wear and tear or misalignment

- Infrared thermography: Identify heat signatures that indicate potential overheating, excessive friction, or bearing failure

- Ultrasonics: Pinpoints defects in rotating machinery components, such as cracks, excessive wear, or loose bearings

- Oil analysis: Provides insights into fluid condition, contamination levels, and the presence of contaminants that can lead to premature failure

5. Data analysis

Transforming Data into Actionable Insights with Data Analysis and Recommendations

Our experts meticulously analyse the collected data using proprietary algorithms and deep industry expertise. We identify anomalies or trends that indicate potential issues, providing clear and actionable recommendations for corrective actions. These recommendations are tailored to your specific requirements, ensuring that you’re always taking informed and timely decisions to maintain operational excellence.

Key Insights from Data Analysis:

- Identification of root causes of asset issues

- Recommendations for appropriate maintenance actions

- Prioritization of corrective actions based on severity

- Clear instructions and guidance for implementing corrective actions

6. Reporting

We utilise our advanced web-based reporting platform, Asset Insight 365, to provide you with a centralized repository of all your CBM data, analysis, and recommendations.

This user-friendly platform allows you to easily visualise trends, compare asset performance, and identify patterns that may indicate impending failures. Additionally, the platform integrates seamlessly with your EPM system, enabling you to seamlessly integrate CBM data into your existing maintenance management workflows.

Empowering insights with real-time dashboards:

- Real-time asset performance dashboards provide a quick overview of asset health and potential issues.

- Trend analysis and predictive modelling identify emerging trends that may indicate impending failures.

- Comprehensive asset health reports provide detailed information on asset performance across multiple dimensions.

- Customisable views and filters allow you to tailor reports to your specific needs.

- Integration with existing EPM systems ensures seamless data integration and reporting.

7. Continuous improvements

In the dynamic world of industrial operations, maintenance strategies must evolve to adapt to changing plant conditions, asset performance, and technological advancements.

That’s why we embed a steadfast commitment to continuous improvement into our CBM implementation process. Regular reviews and optimisation sessions ensure that your CBM program remains aligned with your evolving objectives, ensuring it delivers maximum value and efficiency.

Key elements of continuous improvement:

-

Data-driven insights: We analyse CBM data to identify areas for improvement, refine our recommendations, and optimise our predictive maintenance models.

-

Collaborative engagement: We actively engage with your team to gather feedback, identify specific challenges, and tailor our approach to their unique needs.

-

Technology integration: We leverage emerging technologies and data analytics to enhance the effectiveness of our CBM program, ensuring it remains at the forefront of innovation.

-

Tailored solutions: We continuously refine our CBM program to address evolving industry standards, regulatory requirements, and your specific plant operations.

Outcomes of continuous improvement:

-

Enhance asset reliability: By optimising maintenance strategies, we minimise unplanned downtime and maximize asset utilization.

-

Reduce maintenance costs: We optimise the frequency and scope of maintenance interventions, leading to significant cost savings.

-

Improved predictive accuracy: We continuously refine our predictive models, enabling us to anticipate potential failures with greater precision.

-

Enhanced data-driven decision-making: We empower your team to make informed maintenance decisions based on real-time asset insights.

How our CBM solutions can benefit you

Detect problems early

Non-intrusive CBM techniques meticulously assess the subtle signs of impending failure, alerting you well in advance of potential breakdowns. This early warning system empowers you to address issues promptly, preventing costly downtime and production disruptions.

Embrace proactive maintenance

CBM doesn't just detect problems – it empowers you to take proactive action. Our expertise guides you in transitioning from a reactive maintenance mindset to a proactive one, where maintenance is scheduled based on actual asset condition, not arbitrary intervals. This paradigm shift ensures that maintenance interventions are performed only when required, optimising resources and minimising unnecessary expenses.

Reduce maintenance costs

With CBM, you'll say goodbye to excessive maintenance costs. By eliminating unnecessary preventive maintenance and reacting to potential issues before they escalate, you'll effectively control maintenance expenditures. Further, our expert guidance helps you optimise maintenance schedules, ensuring that resources are allocated where they're needed most, maximising value for your investment.

Tailored CBM programs

We understand that every plant and its unique operating environment present distinct challenges and objectives. That's why our CBM solutions are meticulously tailored to your specific needs, ensuring a high return on investment (ROI). Through a comprehensive assessment of your goals, budget, and processes, we craft a custom CBM program that delivers tangible and measurable benefits.

Did you know...

50%

less unplanned downtime was recorded by organisations that use CBM practices

15%

was saved on maintenance costs by organisations that use CBM.

30%

less asset failures were recorded by organisations that use CBM versus organisations who don’t.

Why choose us?

Hear what our customers have to say

We care about the journey we take our customers on, but it’s not our word you should be taking, see what our customers think of the service we provided!

FAQs

What are the different types of CBM?

+

There are many types of CBM but the most common ones are:

1. Predictive Maintenance: This is a type of maintenance that uses data from condition monitoring to predict when a failure is likely to occur it allows you to take corrective action before the failure happens.

2. Preventive maintenance: This is a scheduled maintenance program that is designed to prevent failures. This type of maintenance is typically based on time or usage intervals, and it often includes tasks such as lubrication, cleaning, and inspection.

3. Reactive maintenance: This maintenance approach is based around fixing issues as they arise. It’s the least proactive and most often the most expensive.

What are the challenges of implementing CBM?

+

There are several challenges that a business may face if they decide they want to implement CBM. The most common challenges are:

1. Data analysis: Once the data has been collected it need to be analysed by an experienced engineer to be able to identify any potential issues.

2. Resistance to change: If a business has always operated with reactive maintenance techniques, it can be difficult to change the mindset of those in charge to see the benefits even though they can be significant.

How do I choose the right CBM solution for my business?

+

To choose the right CBM solution you will need to consider the following:

1. Your budget: CBM solutions can vary depending on the size of the business requirements and the current maintenance strategy.

2. Your requirements: Different CBM solutions are better suited to small scale operations where others are more suited to larger scale.

3, Your goals: Why do you want to introduce CBM to your business? Do you have particular results you want to see? Are you wanting to reduce your equipment downtime? Do you want to save maintenance costs?